Soo saaraha Qaybaha Milling CNC Custom

Farsamaynta makaanikada inta badan waa habaynta gacanta iyo habaynta CNC laba qaybood.Farsamaynta gacanta waxa loola jeedaa habka agabka kala duwan iyadoo gacanta lagu hawlgelinayo qalabka farsamada sida mishiinada wax-shiidka, alwaaxyada, mishiinada qodista iyo mishiinada alwaaxda.Nidaaminta gacanta ayaa ku habboon dufcad yar, wax soo saarka qaybo fudud.

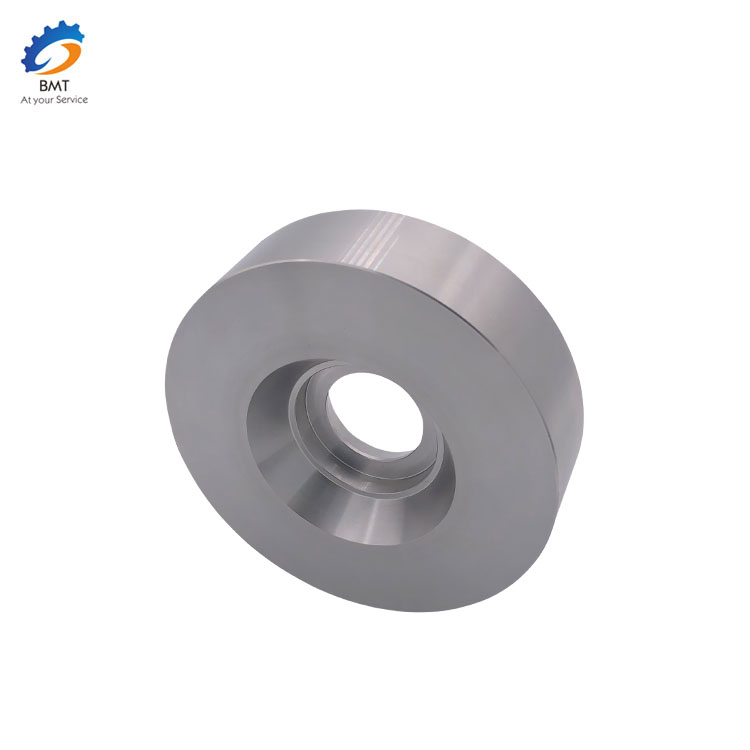

Mashiinka xakamaynta nambarada (CNC) waxaa loola jeedaa shaqaalaha mishiinada inay isticmaalaan qalabka xakamaynta nambarada si ay u wadaan farsamaynta, qalabkan xakamaynta nambarada waxaa ka mid ah xarunta machining, xarunta wax lagu shiidayo, qalabka goynta wedM, mashiinka goynta dunta iyo wixii la mid ah.Aqlabiyadda aqoon-is-weydaarsiyada farsamaynta mishiinnada waxay adeegsadaan tignoolajiyada habaynta tirooyinka.Iyada oo loo marayo barnaamijka, workpiece ee nidaamka isku-dubarid ee Cartesian isku-duwayaasha booska (X, Y, Z) galay luqadda barnaamijka, CNC mashiinka CNC kantaroolaha iyada oo loo marayo aqoonsiga iyo tarjumaadda luqadda barnaamijka si loo xakameeyo dhidibka qalabka mashiinka CNC, si toos ah ka saar. maaddada sida waafaqsan shuruudaha, si loo helo dhamaystirka shaqada.Mashiinka CNC wuxuu u maareeyaa workpiece si joogto ah, oo ku habboon tiro badan oo qaybo qaab adag ah.

Farsamaynta farsamaynta

Qalabka mashiinka CNC waxaa si toos ah loogu habayn karaa nidaamka CAD/CAMJoometry ee qaybaha si toos ah ayaa looga rogaa nidaamka CAD oo loo beddelaa nidaamka CAM, shaqaalaha mashiinka ayaa dooranaya hababka mashiinnada kala duwan ee shaashadda bandhigga.Marka shaqaalaha mashiinka uu doorto habka mashiinnada, nidaamka CAD / CAM wuxuu si toos ah u soo saari karaa koodhka CNC, badiyaa koodhka G, oo geli kara koodhka xakamaynta qalabka mashiinka CNC ee hawlgalka mashiinka dhabta ah.

Qalabka ku yaala dhabarka dambe ee warshadda, sida qalabka biraha wax lagu gooyo (oo ay ka mid yihiin leexinta, wax-shiidka, diyaarinta, galinta iyo qalabyada kale) haddii qaybaha qalabka wax-soo-saarka loo baahan yahay ay jabaan oo u baahan in la hagaajiyo, waxay u baahan tahay in la hagaajiyo. loo diro dukaanka mishiinka si loo dayactiro ama loo habeeyo.Si loo xaqiijiyo wax-soo-saarka wanaagsan, shirkadda guud waxay leedahay aqoon-is-weydaarsi mashiineed, oo inta badan mas'uul ka ah dayactirka qalabka wax-soo-saarka.