Soo saaraha Qaybaha leexashada CNC

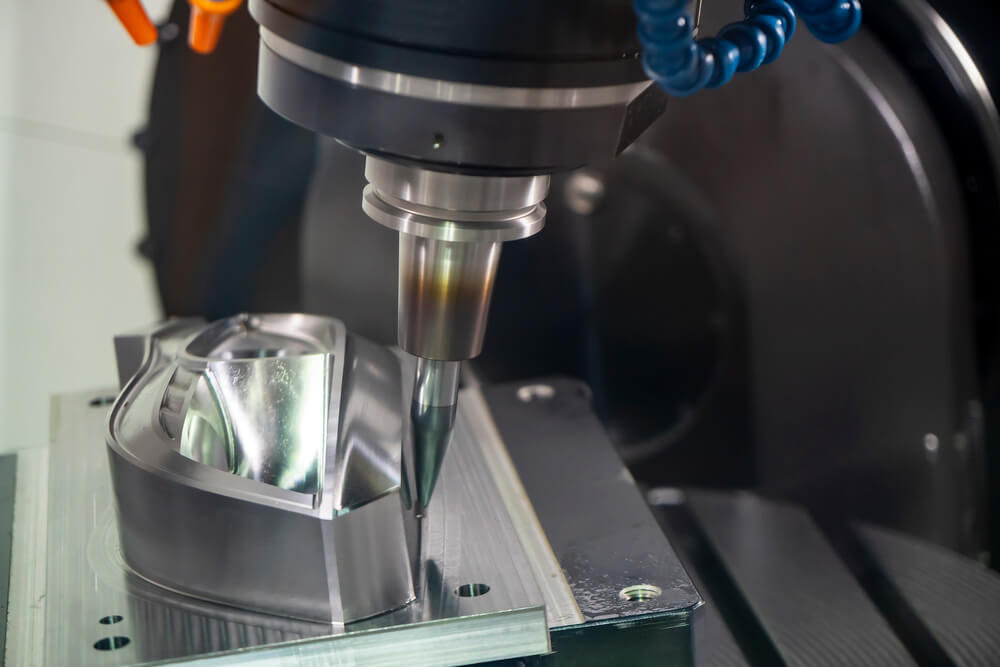

Xarunta mishiinada shanta dhidibka ah waxa kale oo loo yaqaan xarun machining shan-dhidib ah.Waa tignoolajiyad sare, xarun farsamayneed oo sax ah oo si gaar ah loogu isticmaalo ka shaqaynta sagxadaha qaloocan ee kakan.Nidaamkan xarunta makiinadu waxa uu muhiim u yahay duulista, hawada sare, millatariga, cilmi baadhista sayniska, iyo saxnaanta dalka.Warshadaha sida qalabka iyo qalabka caafimaadka ee saxda ah ayaa leh saameyn go'aan leh.Nidaamka mashiinnada shanta dhidibka ah ee CNC waa habka kaliya ee lagu xallinayo farsamaynta impellers, garbaha, mareennada badda, rotors koronto-dhaliyaha culus, rotors marawaxadaha uumiga, mashiinnada waaweyn ee naaftada, iyo wixii la mid ah.

Xarunta mishiinada shanta dhidibka ah waxay leedahay sifooyinka waxtarka sare iyo saxnaanta sare, iyo mashiinada adag waxaa lagu dhamayn karaa hal xajin oo ka mid ah shaqada.Waxaa la waafajin karaa habaynta caaryada casriga ah sida qaybaha baabuurta iyo qaybaha dhismaha diyaaradaha.Farqi weyn ayaa u dhexeeya xarunta mishiinada shanta dhidibka ah iyo xarunta mishiinada shan geesoodka ah.Dad badan ayaa garan la' tan oo waxay ku khaldamaan xarunta machining pentahedral inay tahay xarun mishiineed shan geesood leh.Xarunta makiinadaha shanta dhidibka leh waxay leedahay shan faas x, y, z, a, iyo c.xyz iyo faashashku waxay sameeyaan habayn isku xidhid shan dhidib ah.Waxay ku fiican tahay habaynta dusha sare ee meel bannaan, habaynta qaab gaar ah, farsamaynta godan, feedhitaanka, dalool goynta, goynta goynta, iwm. Isla mar ahaantaana, laakiin ma samayn karto mashiin qaab gaar ah, godadka jeexjeexan, googoyooyinka, iwm.

Software-ka jilitaanka ee sida caadiga ah loo isticmaalo xarumaha mishiinada shanta dhidibka ah waxa loo yaqaan PITAGORA.Muxuu qabtaa software-kani?

Caadi ahaan, marka aan ku shaqayno qalabka shan-dhidibka ah ee farsamaynta, waxaan u baahanahay inaan horay u sii diyaarino ama samayno sawirro.Dhibaatooyinka hawlgalka gacanta awgeed, waxay keeni kartaa ama keeni kartaa khaladaadka barnaamijka, taas oo si lama huraan ah u horseedi doonta dhacdo saameyn leh, taas oo waxyeello u geysan karta qalabka.Software-ka PITAGORA waxa loo isticmaalaa in lagu sawiro habaynta dhabta ah.Waxay saadaali kartaa haddii uu jiro qalad horay u dhacay, si loo yareeyo heerka shilka ugu yaraan loona hubiyo badbaadada qalabka!

Marka la soo koobo,

Xarunta mishiinada shan-dhidibka ah ma aha oo kaliya loo isticmaalo warshadaha rayidka ah, sida warshadaynta caaryada alwaax, gooyn musqusha, farsamaynta qaybaha baabuurta ee gudaha, farsamaynta caaryada xumbo, alaabta guriga ee qaabka Yurub, kuraasta alwaax adag, iwm, laakiin sidoo kale si ballaaran ayaa loo isticmaalaa duulista. , hawada sare, ciidamada, cilmi baarista sayniska, Qalabka saxda ah, qalab caafimaad oo sax ah oo sareeya iyo warshado kale.Xarunta mishiinada shanta dhidibka ah waa hab tignoolajiyada sare leh oo ka dhigaysa wax aan macquul ahayn.Dhammaan sagxadaha qaloocan iyo mashiin qaabaysan ayaa la dhammaystiri karaa.Ma aha oo kaliya in ay dhamaystirto hawsha farsamaynta farsamaynta ee workpieces adag, laakiin sidoo kale si dhakhso ah u wanaajiso hufnaanta processing iyo gaabin hababka processing.

Fariintaada noo soo dir:

-

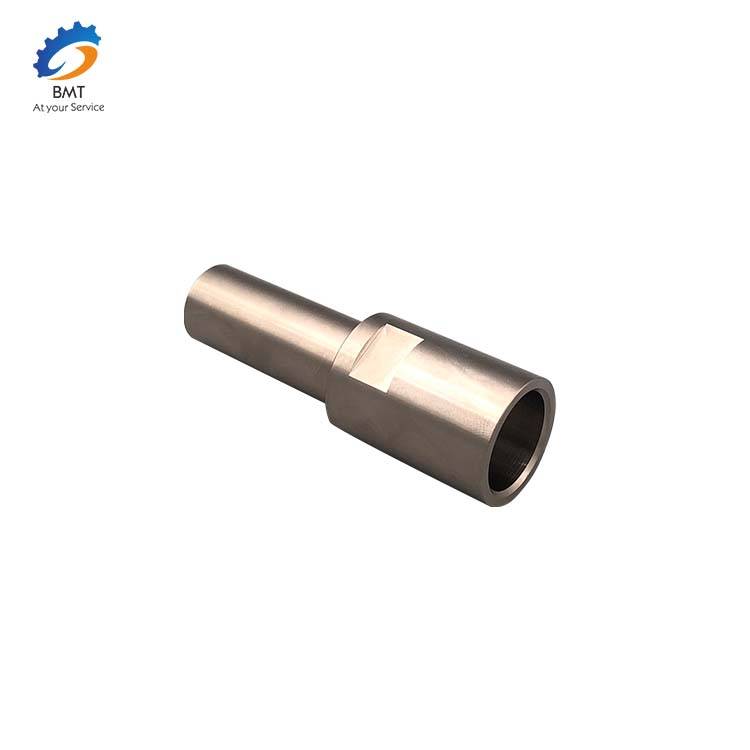

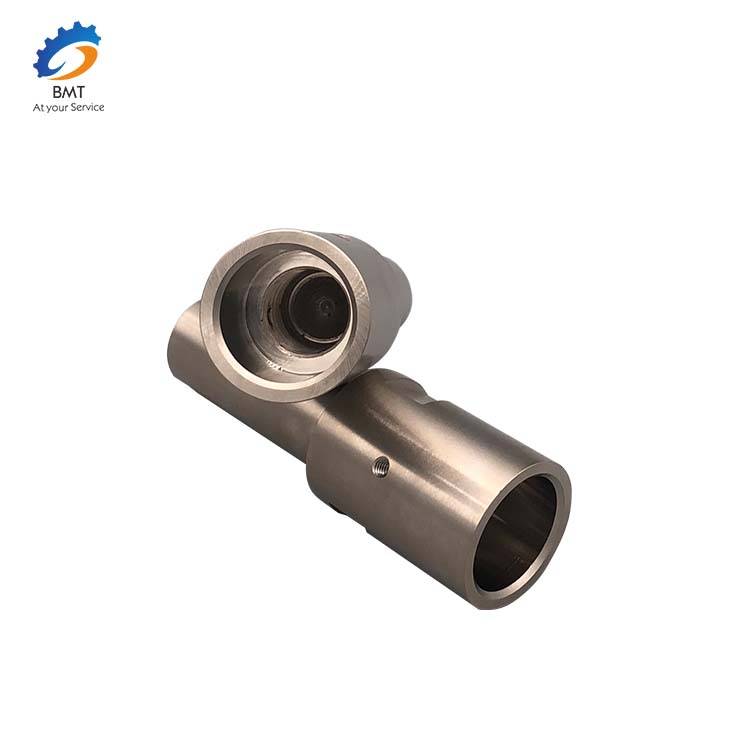

Aluminium CNC Qaybaha Mashiinka

-

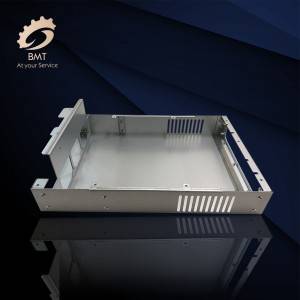

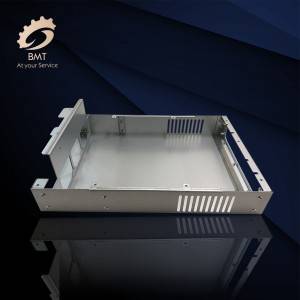

Samaynta Biraha Sheet Aluminium

-

Mashiinka Qaybaha Gawaarida

-

Qaybaha Mashiinnada CNC ee Saxda Sare ee dhidibka

-

Qaybaha CNC Machined

-

Qaybaha Aluminium Machining CNC

-

Qaybaha Biraha ee CNC Machining

-

Qaybaha leexinta Adeegga Mashiinka ee CNC

-

Qaybaha Mashiinnada Milling CNC

-

Qaybaha xaashida hawada ee gaarka ah