Kala soocidda Mashiinnada wax lagu shiilo

Iyadoo kororka tiradasaxnaanta sareiyo qaybo ka mid ah qallafsanaanta sare ee farsamada, iyo sidoo kale horumarinta tignoolajiyada saxda ah ee saxda ah iyo teknoolajiyada been abuurka ah, waxqabadka, kala duwanaanta iyo wax soo saarka mashiinnada wax lagu shiido ayaa si joogto ah u wanaajinaya oo sii kordhaya.

(1) Booqday Furimaha Dagaalka:Waa taxane aasaasi ah oo nooc caadi ah, oo inta badan loo isticmaalo shiididda sagxadaha cylindrical iyo conical dibadda.

(2) Furimaha gudaha:Waa taxane nooc oo caan ah, oo inta badan loo isticmaalo shiididda sagxadaha cylindrical iyo conical gudaha.

(3) Isku-dubarid Furimaha Dagaalka:Furimaha gudaha oo leh qalab meelaynta saxda ah.

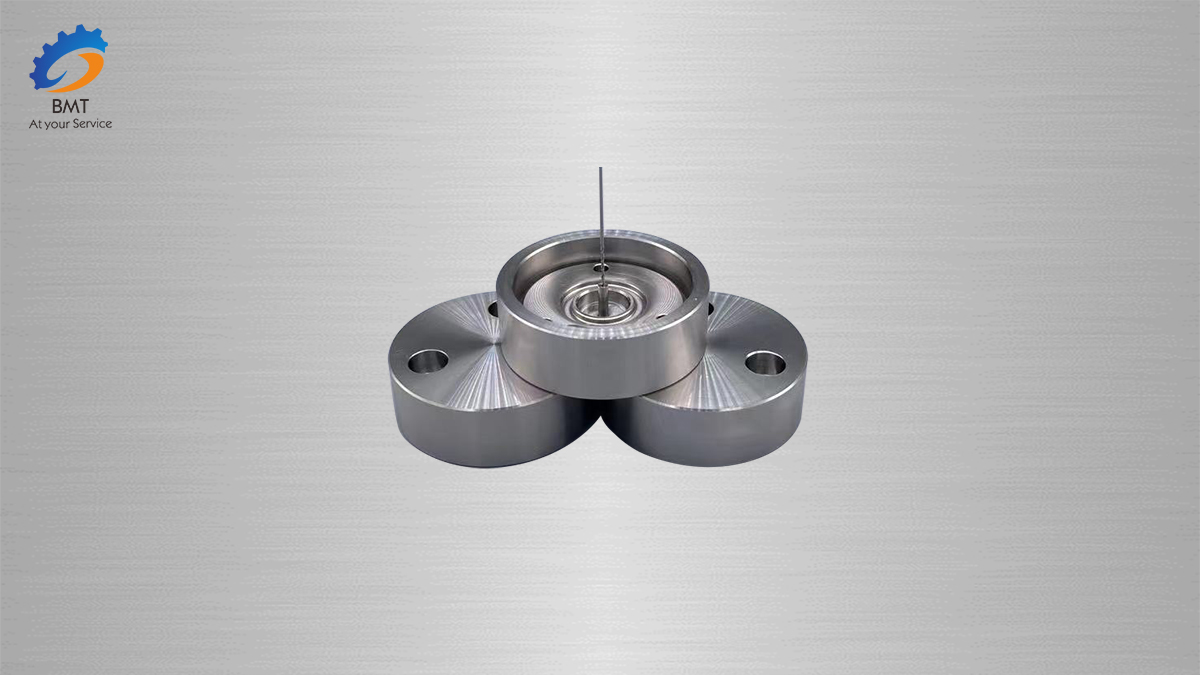

(4) Furimahade aan dhexda lahayn:Qalabka shaqada waxa uu ku xidhan yahay bilaa dhexe, guud ahaan waxa taageera inta u dhaxaysa giraangiraha hagaha iyo xidhmada, iyo shaadhka hagaha ayaa u kaxeeya qaybta shaqada si uu u wareego. Waxaa inta badan loo isticmaalaa shiididda sagxadaha cylindrical.

(5) Furaha dusha sare: inta badan loo isticmaalo shiidi dusha workpiece.

(6) Furimahaaga suunka xoqan:Furimaha isticmaala suunka xoqidda dhaq-dhaqaaqa degdega ah ee shiididda.

(7) Mashiinka hoing:Waxaa loo isticmaalaa in lagu hagaajiyo meelaha kala duwan ee workpieces.

(8) Shiiqiyaha:Waxaa loo isticmaalaa in lagu shiido gudaha iyo dibadda dusha diyaaradda workpiece ama dhululubo.

(9) Tilmaanta Furimaha Dagaalka:inta badan loo isticmaalo shiidi dusha tareenka hagaha ee qalabka mashiinka.

(10) Furaha qalabka:Furimaha loo isticmaalo wax lagu shiidi karo.

(11) Mashiinka wax lagu shiido ujeedooyin badan:Waxaa loo isticmaalaashiidida cylindricaliyo sagxadaha gudaha iyo dibadda ee koonka ah ama diyaarado, waxayna isticmaali karaan qalabka servo iyo accessories si ay u shiidaan qaybo kala duwan oo shaqo ah.

(12) Mashiinka wax shiida ee gaarka ah:qalab gaar ah oo mishiinka loo isticmaalo shiidi qaybo gaar ah. Marka loo eego walxaha farsamaynta, waxa loo qaybin karaa Furimaha Dagaalka usheeda dhexe, Furimaha Dagaalka crankshaft, Booqday Furimaha Dagaalka, Furimaha Dagaalka, Furimaha Dagaalka, Furimaha Dagaalka, iwm.

Ilaalinta Badbaadada

shiididsi weyn ayaa loo isticmaalaa waana mid ka mid ah hababka ugu muhiimsan ee saxsanaanta mashiinnada qaybaha mashiinka. Si kastaba ha ahaatee, xawaaraha sare ee giraangiraha wax shiida awgeed, giraangiraha shiidadu waa adag yahay, jajaban yahay, uma adkeysan karo saameyn culus. Hawlgalka aan habboonayn ee mararka qaarkood waxay keeni doontaa cawaaqib xun haddii giraangiraha shiida uu jabo. Sidaa darteed, shaqada farsamada badbaadada ee shiididu waa muhiim gaar ahaan. Aaladaha ilaalinta badbaadada ee la isku halayn karo waa in la qaataa, hawlgalkuna waa in la xoojiyaa si loo hubiyo in aanay khatari jirin.Intaa waxaa dheer, jajabyada ciid wanaagsan iyo jajabyada birta ah ee ka soo firdhiyey qaybta shaqada ee giraangiraha wax lagu shiido inta lagu jiro shiidadu waxay dhaawici doontaa indhaha shaqaalaha. Haddii shaqaaluhu ay neefsadaan xaddi badan oo boodhkan ah, waxay dhaawac u geysan doontaa caafimaadkooda, waana in sidoo kale la qaado tallaabooyin ilaalin ah oo ku habboon. Dhibaatooyinka farsamada ee soo socda ee badbaadada waa in fiiro gaar ah loo yeesho inta lagu jiro shiida.

Fariintaada noo soo dir:

-

Aluminium CNC Qaybaha Mashiinka

-

Samaynta Biraha Sheet Aluminium

-

Qaybaha Mashiinnada CNC ee Saxda Sare ee dhidibka

-

Qaybaha CNC Machined ee Talyaaniga

-

Qaybaha Aluminium Machining CNC

-

Mashiinka Qaybaha Gawaarida

-

Titanium Alloy Forgings

-

Titanium iyo Titanium Alloy Fittings

-

Titanium iyo Titanium Alloy Forgings

-

Titanium iyo Titanium Alloy Wires

-

Baararka Titanium

-

Tubooyinka/tubooyinka Titanium Aan Aan Lahayn

-

Tubooyinka alxanka ah ee Titanium