Titanium iyo Titanium Alloy Wires

Titanium saafi ah waa bir cad oo silvery ah, taas oo leh sifooyin aad u fiican.Titanium cufnaanta 4.54g/cm3, 43% ka fudud birta oo wax yar ka culus magnesium birta iftiinka ee sharafta leh.Laakin awooda makaanikadu waxay la mid tahay birta, laba jeer way ka xoog badan tahay aluminium iyo shan jeer ka xoog badan magnesium.Titanium waa mid u adkaysata heerkulka sare waxayna leedahay meel dhalaalaysa 1942K, ku dhawaad 1000K ayaa ka sarreeya dahabka iyo ku dhawaad 500K oo ka sarreeya birta.

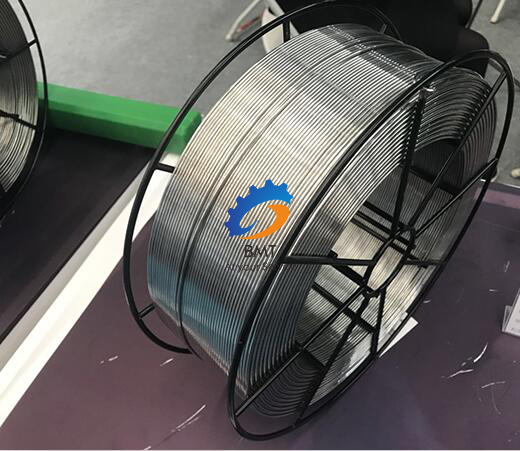

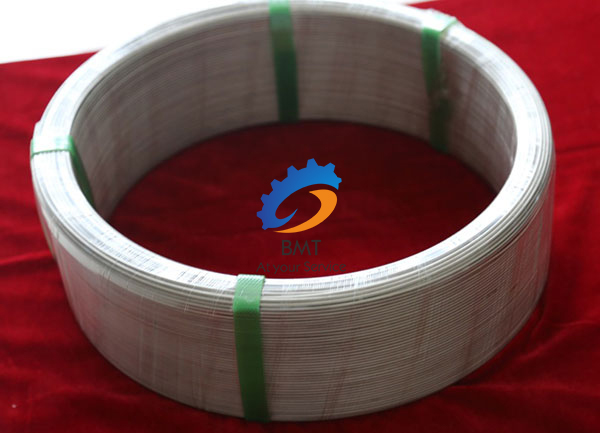

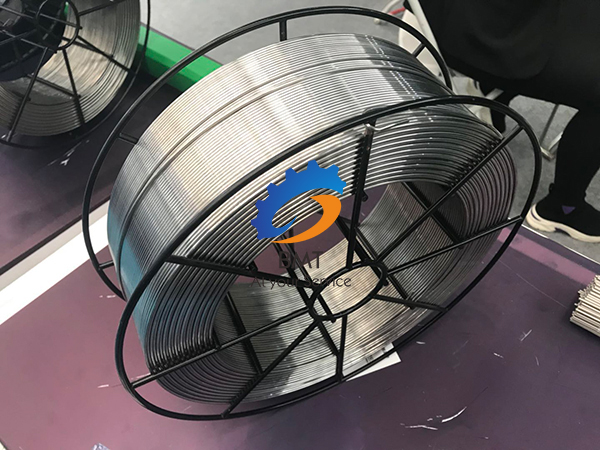

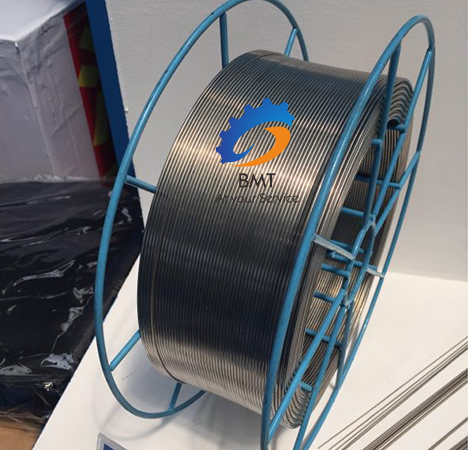

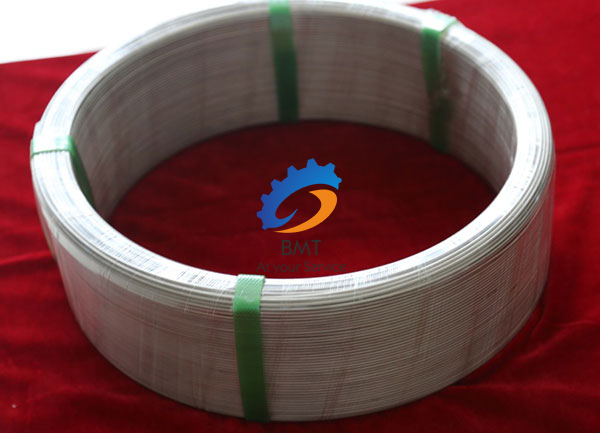

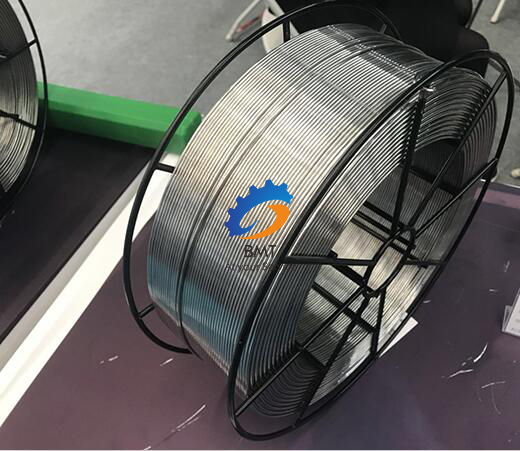

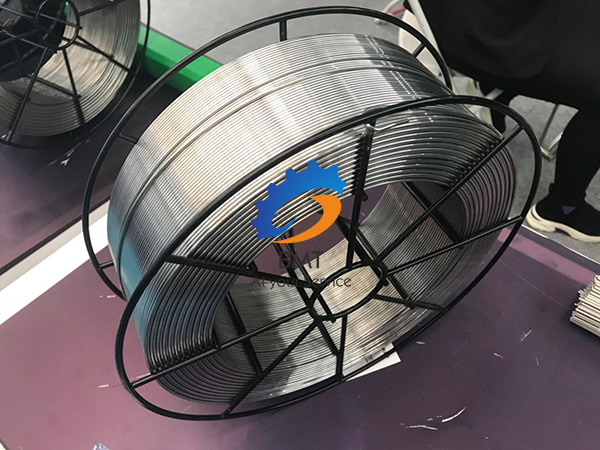

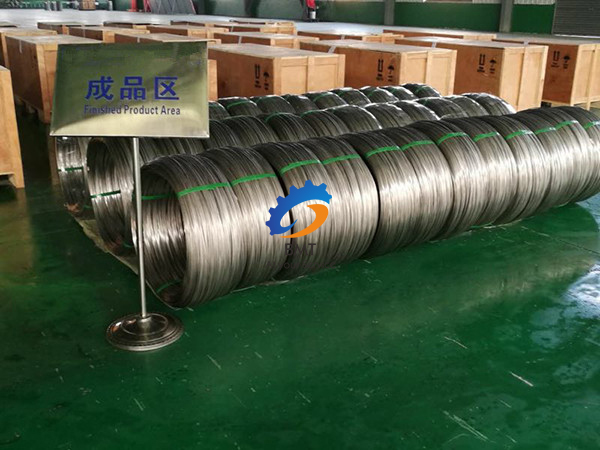

Siligga Titanium waxaa loo qaybiyaa: silig titanium, silig aluminium titanium, fiilada titanium saafi ah, silig titanium toos ah, silig titanium saafi ah, silig titanium alxanka, titanium ka laadlaadda silig, titanium disk silig, titanium dhalaalaya silig, silig titanium caafimaad, titanium nickel alloy silig .

Tilmaamaha Siliga Titanium

A.Tilmaamaha siliga Titanium: φ0.8-φ6.0mm

B.Muraayadaha siligga titanium: φ1.0-φ6.0mm silig titanium gaar ah

C.Tilmaamaha siligga Titanium: φ0.2-φ8.0mm oo leh laalaad gaar ah

Heerka:GB/T,GJB,AWS,ASTM,AMS,JIS

Darajada fiilada Titanium

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, iwm.

Goobaha Codsiga ee Wire Titanium

Warshadaha militariga, caafimaadka, alaabta ciyaaraha, muraayadaha, hilqado, dharka madaxa, korantada laalaada, siliga alxanka iyo warshado kale.

Gobolka Titanium Wire

Gobolka Annealing (M)

Xaalada kulul ee shaqada (R)

Xaalad shaqo qabow (Y)

(Annealing, Tijaabada Jiilka Sare)

Dusha sare ee fiilada Titanium

Oogada oogada ama korka dhalaalaysa

Siligga Titanium wuxuu sameeyaa kaarbiid deggan oo leh engegnaan sare oo leh kaarboon.Kobaca lakabka kaarboonka leh ee u dhexeeya titanium iyo kaarboon waxaa lagu go'aamiyaa heerka fidinta titanium-ka ee lakabka carbonized.

Solubility ee kaarboon ee titanium waa yar yahay, oo gaaraya 0.3% at 850X: oo hoos u dhacay ilaa 0.1% at 600C B Sababtoo ah milanka hoose ee kaarboon ee titanium, adkaynta dusha sare ayaa asal ahaan lagu gaaraa kaliya iyada oo loo marayo lakabka carbide titanium iyo akimbo. lakabka hoose.Kaarburintu waa in lagu fuliyaa xaalada ka saarida ogsijiinta, sababtoo ah engegnaanta lakabka sare ee budada sida caadiga ah loo isticmaalo kaarburista birta ee ka soo horjeeda dusha carbon monoxide ama carbon monoxide-ka oksijiin ku jira waa ilaa 2700MPa iyo 8500MPa, iyo mesh.Way fududahay in la iska fujiyo.

Halabuurka Kiimikada Qalabka La heli karo

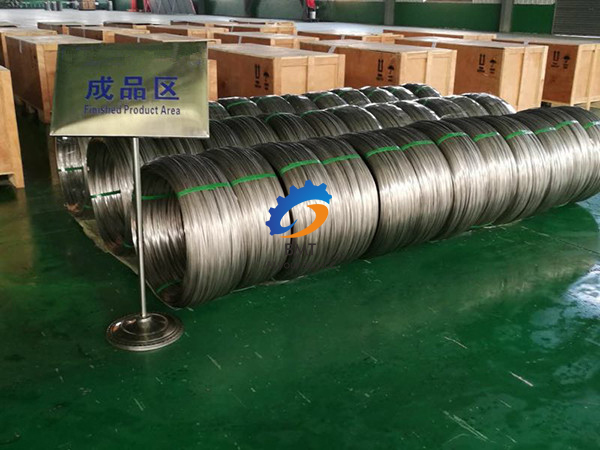

Wax soo saarka (Qaddarka Dalbashada ugu badan iyo ugu yaraan):Unlimited, si waafaqsan amarka.

Waqtiga Hogaaminta:Waqtiga hogaaminta guud waa 30 maalmood.Si kastaba ha ahaatee, waxay kuxirantahay qadarka dalabka si waafaqsan.

Gaadiidka:Habka guud ee gaadiidka waa Badda, by Air, by Express, by Train, kaas oo ay dooran doonaan macaamiisha.

Baakad:

- Cidhifyada tuubooyinka si loogu ilaaliyo koofiyadaha balaastigga ah ama kartoonada.

- Dhammaan qalabka lagu rakibay waa in la soo buuxiyaa si loo ilaaliyo cidhifyada iyo wejiga.

- Dhammaan badeecadaha kale waxaa lagu rari doonaa suufyo xumbo ah iyo baakado caag ah iyo kiis alwaax ah oo la xiriira.

- Qoryaha loo isticmaalo baakadaha waa in uu ahaado mid ku haboon si looga hortago wasakheynta marka la taabto qalabka wax lagu qabto.

.jpg)

Taas bedelkeeda, marka la eego xaaladda deoxygenation ama decarburization, lakabka khafiifka ah ee carbide titanium ayaa laga yaabaa in la sameeyo marka karbuunta dhuxusha.Adag ee lakabkani waa 32OUOMPa, kaas oo la jaan qaadaya adkaanta carbid titanium.Qoto dheer ee lakabka carburizing ayaa guud ahaan ka weyn kan lakabka nitriding marka nitriding loo isticmaalo isla shuruudo isku mid ah.Marka la eego xaaladda kobcinta oksijiinta, saamaynta nuugista ogsijiinta ee qoto-dheeraanta waa in la tixgeliyaa.Kaliya waxay ku hoos jirtaa heerka dhumucda lakabka aadka u dhuuban in xoogga koollada ku filan lagu samayn karo kaarburidka budada kaarboon ee vacuum ama jawiga argon-methane.Taas bedelkeeda, isticmaalka wakiilka carburizing gaaska ayaa laga yaabaa inuu sameeyo lakab adag oo gaar ahaan adag oo si fiican ugu xidhan lakabka adag ee carbide titanium.Isla mar ahaantaana, fiditaanka qallafsanaantu waxay ku samaysmeen heerkulka u dhexeeya 950T: iyo 10201:.Markay korodho dhumucda lakabka, lakabka TiC wuxuu noqdaa mid jajaban oo u janjeera inuu dillaaco.Si looga fogaado faragelinta kaarboonka ku darista lakabka TiC sababtoo ah burburka Reane, kaarburinta gaaska waa in lagu fuliyaa gaas aan shaqaynayn oo lagu daro qiyaasta qiyaasta 2% Reane.Adkeydka dusha hoose waxaa la helaa marka methane lagu daro karbohaydraytyada propane.Marka xoogga isku xidhku gaadho ilaa OKPA iyo gaasta kaarburized propane ayaa la isticmaalaa, in kasta oo dhumucda lakabka adag ee la qiyaasay ay aad u dhuuban tahay, waxay leedahay iska caabbinta xidhashada ugu fiican.Haydaroojiinka waxaa nuuga wakiilka kaarbuuraynta gaaska, laakiin waa in mar kale laga saaraa inta lagu jiro soo saarista faakuumka.