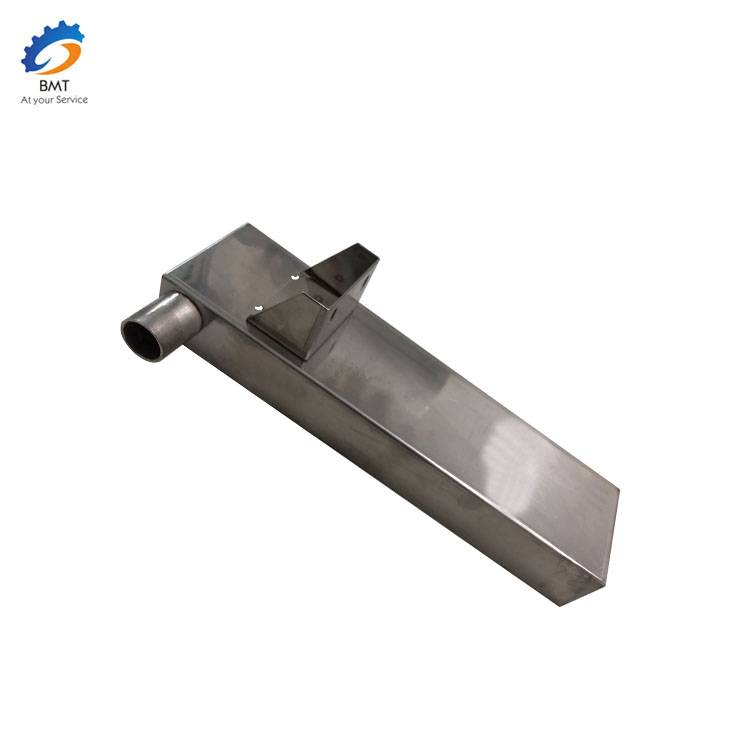

Laacidda Muhiimadda Sheet Metal Works

Inkasta oo foorarsiga birta xaashida ay u muuqato mid aad u fudud, waxay qarinaysaa xeerar iyo tignoolajiyada taxanaha ah ee kuu ogolaanaya inaad garato qaababka fudud ama aadka u adag. Qallooca xaashida waa mid ka mid ah hababka ugu caansan warshadaha wax soo saarka.

Si la mid ah habka samaynta, shaqooyinka foorarsigu waxay abuuraan isbeddel jihada biraha xaashida ah. Tusaale ahaan, biraha fidsan u beddel xaashi xaglo leh. Dhab ahaantii, iyada oo loo marayo isticmaalka saxaafadda CNC, caaryada, mashiinka foorarsiga ama mashiinnada kale, birta xaashida waxay gaari kartaa qaabka geeska.

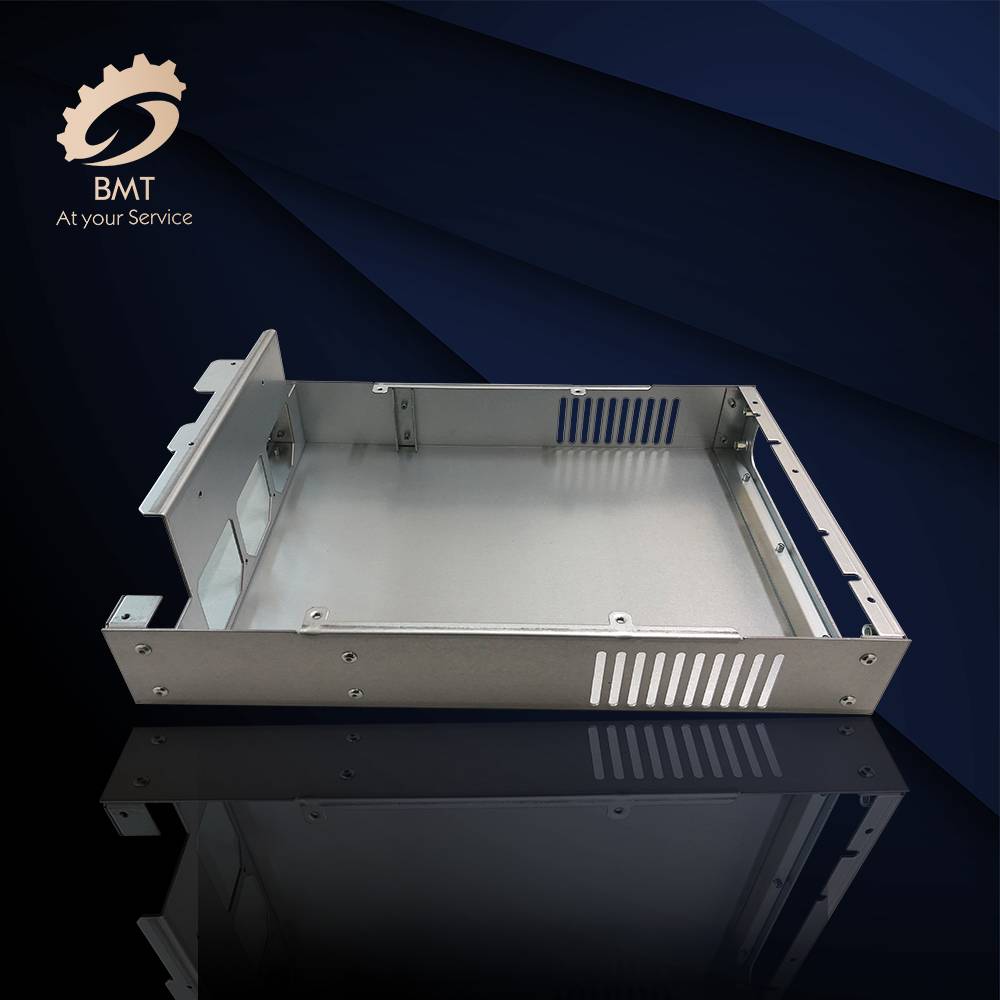

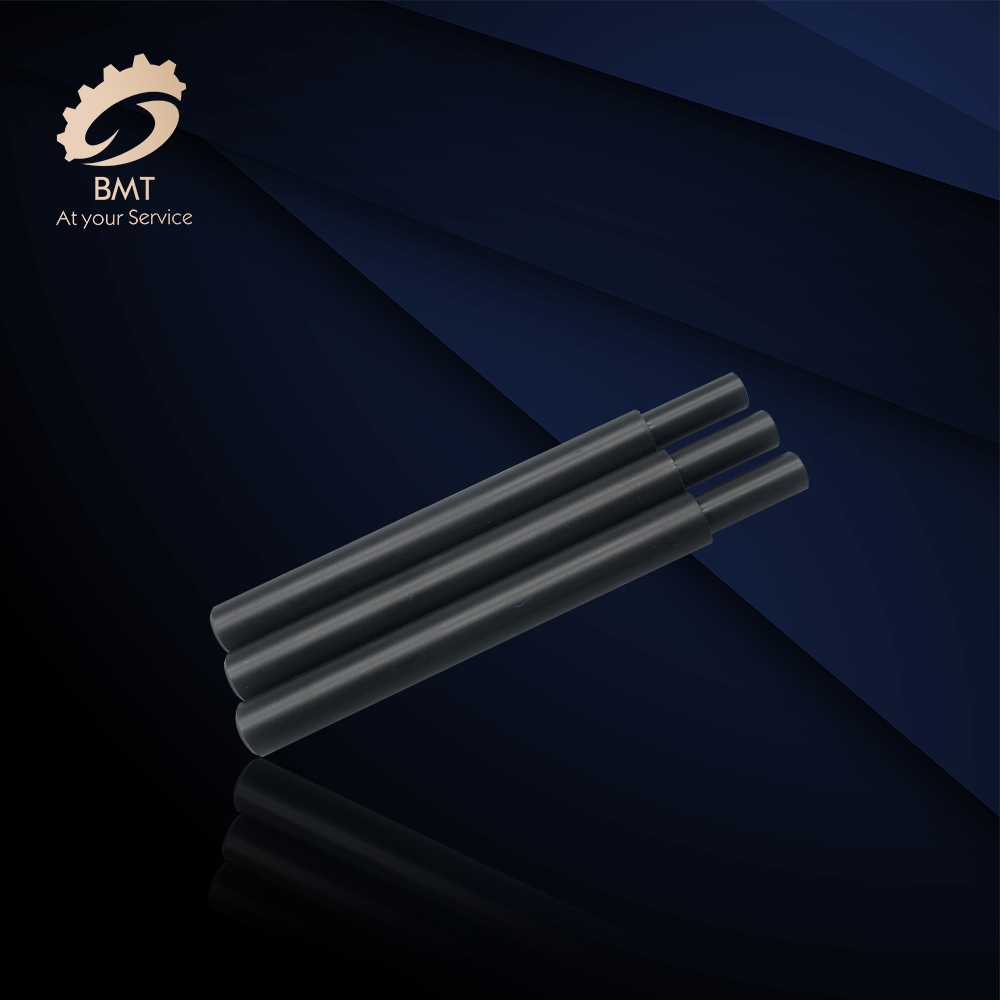

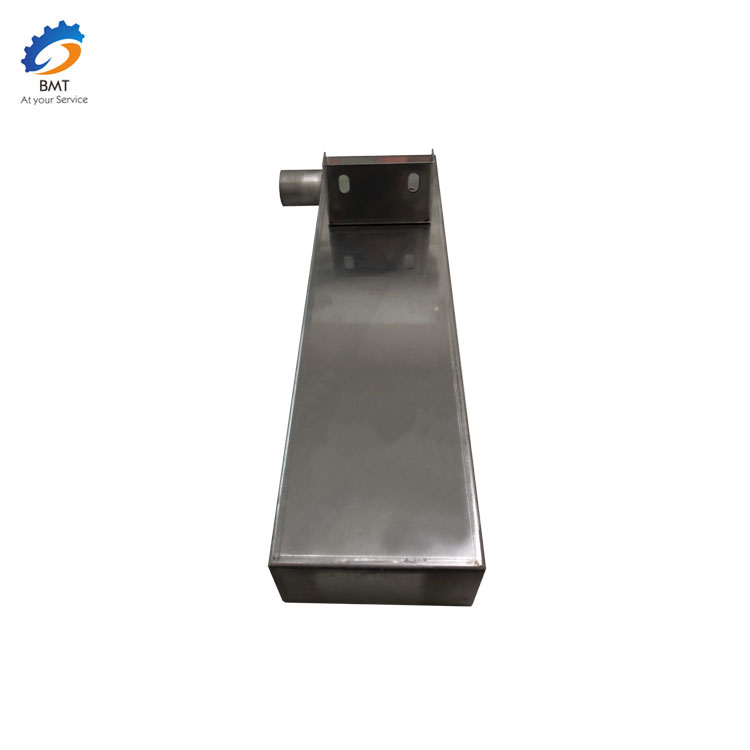

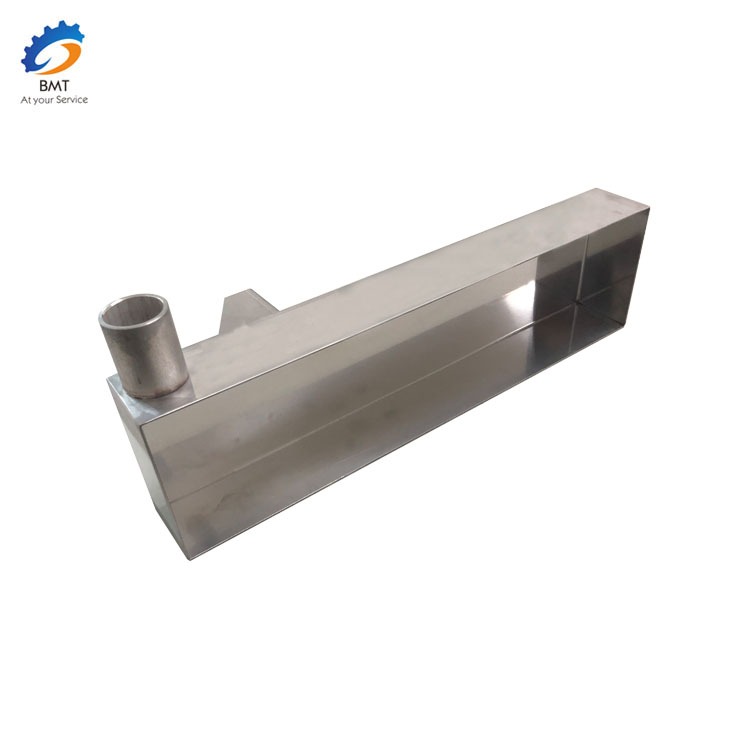

Samaynta biraha xaashida ah waa nidaam kuu ogolaanaya inaad xaqiiqsato qaabab fudud ama aad u adag oo lagu dabaqi karo biro kala duwan: min bir ilaa naxaas, naxaas ilaa aluminium, birta aan la taaban karin ilaa kuwa kale ee gaarka ah.

Markaad u baahan tahay inaad go'aansato nooca foorarsiga, waa inaad tixgelisaa: dhumucda birta, nooca qalooca, xagasha leexinta, iyo cabbirrada shaqada iyo arrimo kale oo muhiim ah oo la xiriira.

Xeerka guud ee arrintan ku saabsan wuxuu noqon karaa: ka weyn waa foorarsiga, heerka hoose ee u dhexeeya caaryada sare iyo hoose. Ku saabsan arrimaha aan hadda soo sheegnay, waxaad dooran kartaa noocyo kala duwan oo foorarsi ah.

Waxaa jira arrimo badan oo saameyn kara natiijadafoorarsan xaashida. Tusaale ahaan, kuwa ugu muhiimsan waa:

1. Qalabka birta ah

2. Cadaadiska ka dhashay habraacii hore

3. Nooca geesaha aad rabto inaad ogaato

4. Dhererka iyo dhumucda qaybta shaqada

5. heerkulka processing

Waxaa jira faa'iidooyin badan oo ka mid ah Wershadaha Sheet Metal, oo ay ku jiraan xulashada walxaha (Aluminium, Copper, Steel Steel iyo kuwa kale), xulashada dhamaystirka (Qaraxyada Bead, Anodizing, Plating, Coating Powder, iwm), xulashada dhumucda ( Iyada oo ku saleysan cabbirada). adkeysiga, scalability, soo celinta degdega ah, iwm. Wixii faahfaahin dheeraad ah, fadlan eeg shaxda hoose.

| NO | WAXYAABAHA | FAAHFAAHIN |

| 1 | Qalab | Aluminium, Steel, Brass, Copper, Stainless steel, Plastics, POM, Derlin, Titanium Alloy, iwm. |

| 2 | Daaweynta Dusha sare | Dahaarka Zinc, Anodization, Filim kiimiko ah, daahan budada ah, Passivation, ciid qarxinta, cadayashada & polishing, iwm. |

| 3 | Qalabka farsamaynta | Cnc Machining Center, CNC Lathe, Mishiinka Wax-shiidka, Mishiinka Late-ka Tooska ah, Mishiinka Late, Mishiinka Wax-shiidka, EDM, iwm. |

| 4 | Qalabka Kormeerka | 3D CMM; 2.5D sawirada qalabka lagu cabbiro, Mitirka qallafsanaanta, caliper slide, micrometers, block gauge, tilmaame garaaca, cabirka dunta, qaanuunka xagasha caalamiga ah, iwm. |

| 5 | Adeegyadayada | CNC Machining, Milling, Turning, Shiidista, Shaabadaynta, Feeraynta, iyo isu-ururinta, iwm. |

| 6 | Nidaamka QC | 100% kormeerka ka hor inta aan la rarin, Kormeerka dhinaca saddexaad ayaa la heli karaa marka la codsado. |

| 7 | Baakad | Xumbo, kartoon, sanduuqyo alwaax ah, sida shuruudaha loo habeeyey. |

| 8 | Shuruudaha Lacag-bixinta | 30% T / T ka hor, 70% dheelitirka ka hor inta aan la dhoofin. |

| 9 | Baaxadda Alaabta | Mashiinka CNC / rogista qaybaha, Jig & Naqshadeynta Naqshadeynta iyo Sameynta, Qaybaha Sheet Biraha iyo Qaybaha Shaabadda. |

| 10 | Codsiga | Mashiinka Automation-ka, Mashiinka Warshadaha, Qalabka Korontada, Qaybaha Gawaarida, Qaybaha Alaabada, Qaybaha Mashiinada, Qalabka Iftiinka, iwm. |

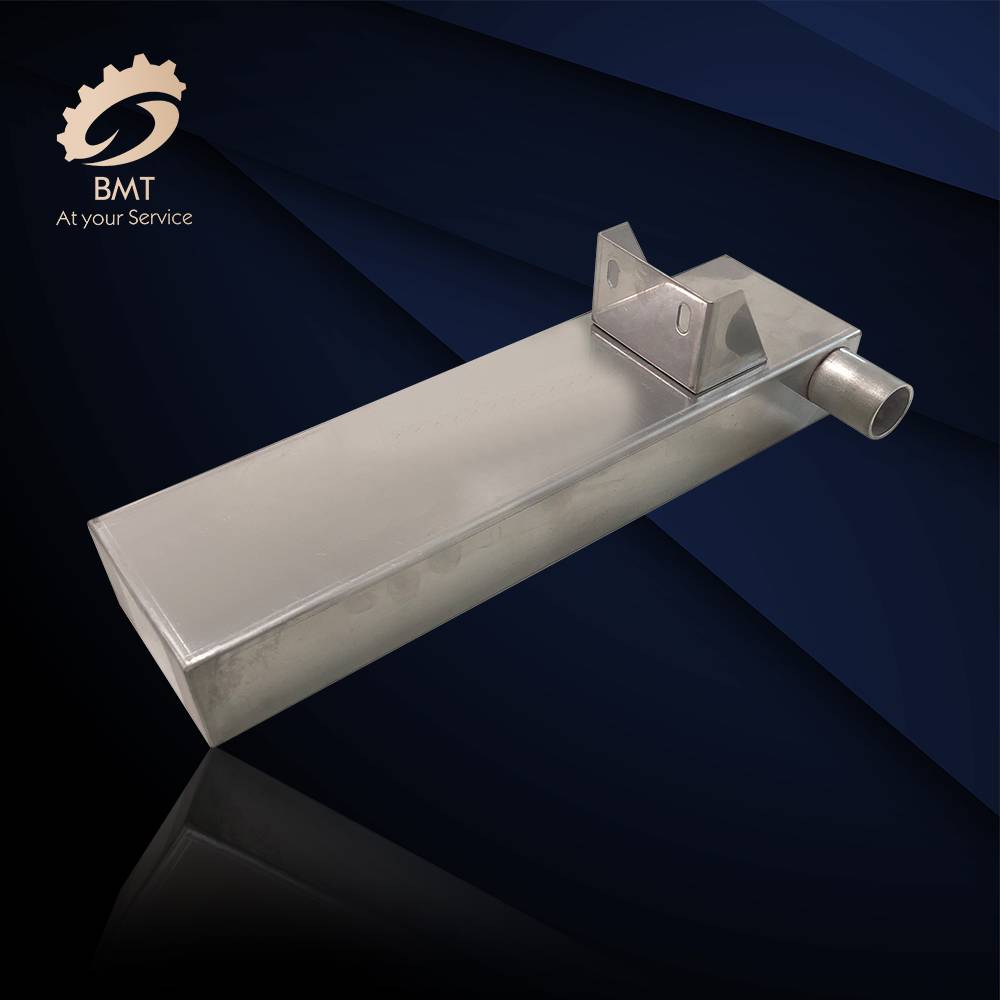

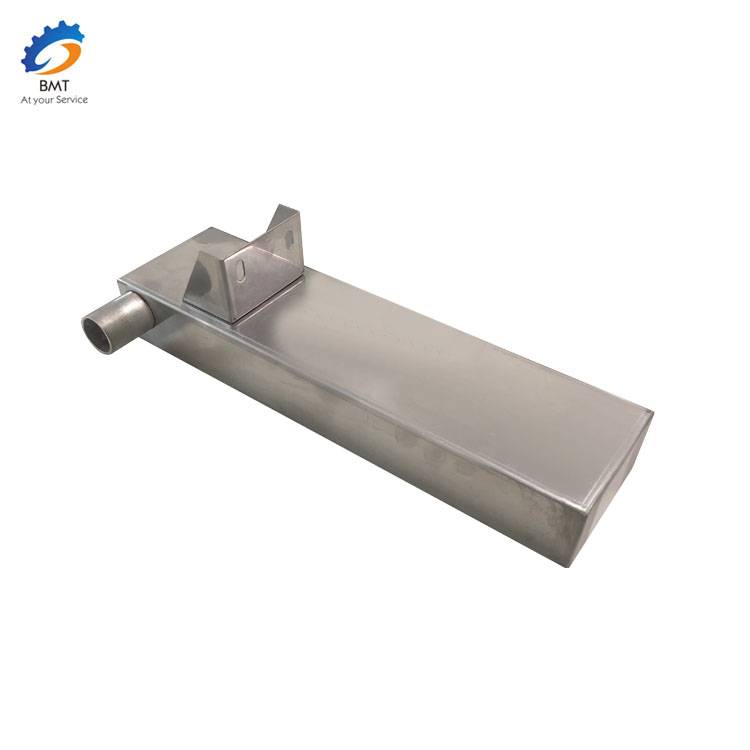

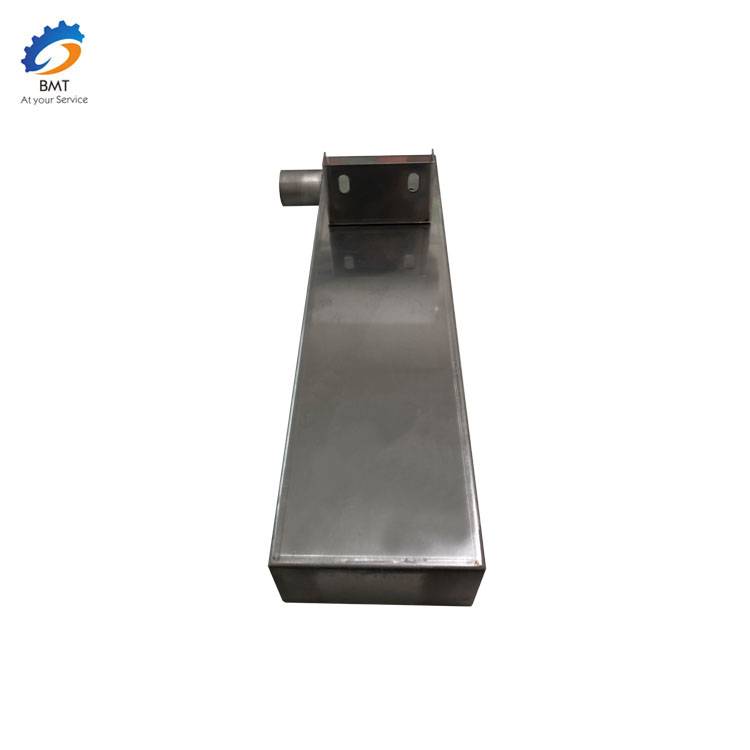

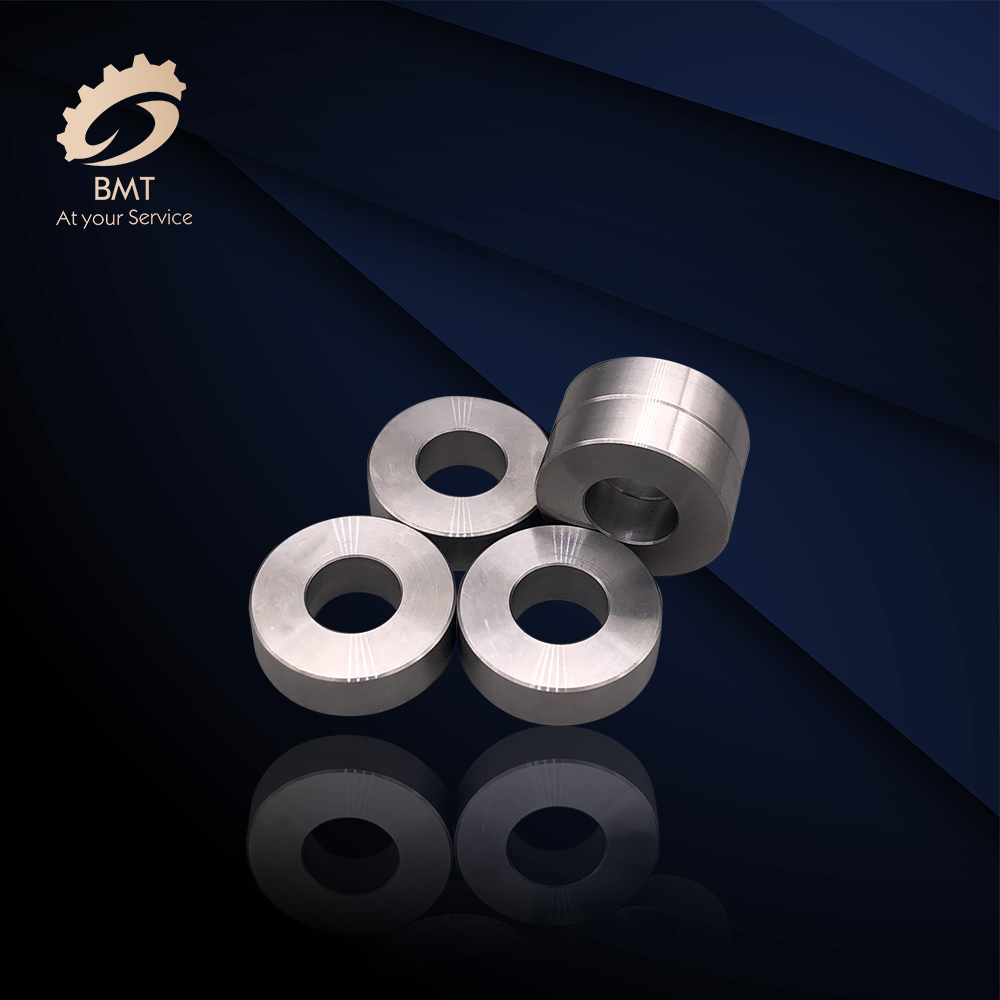

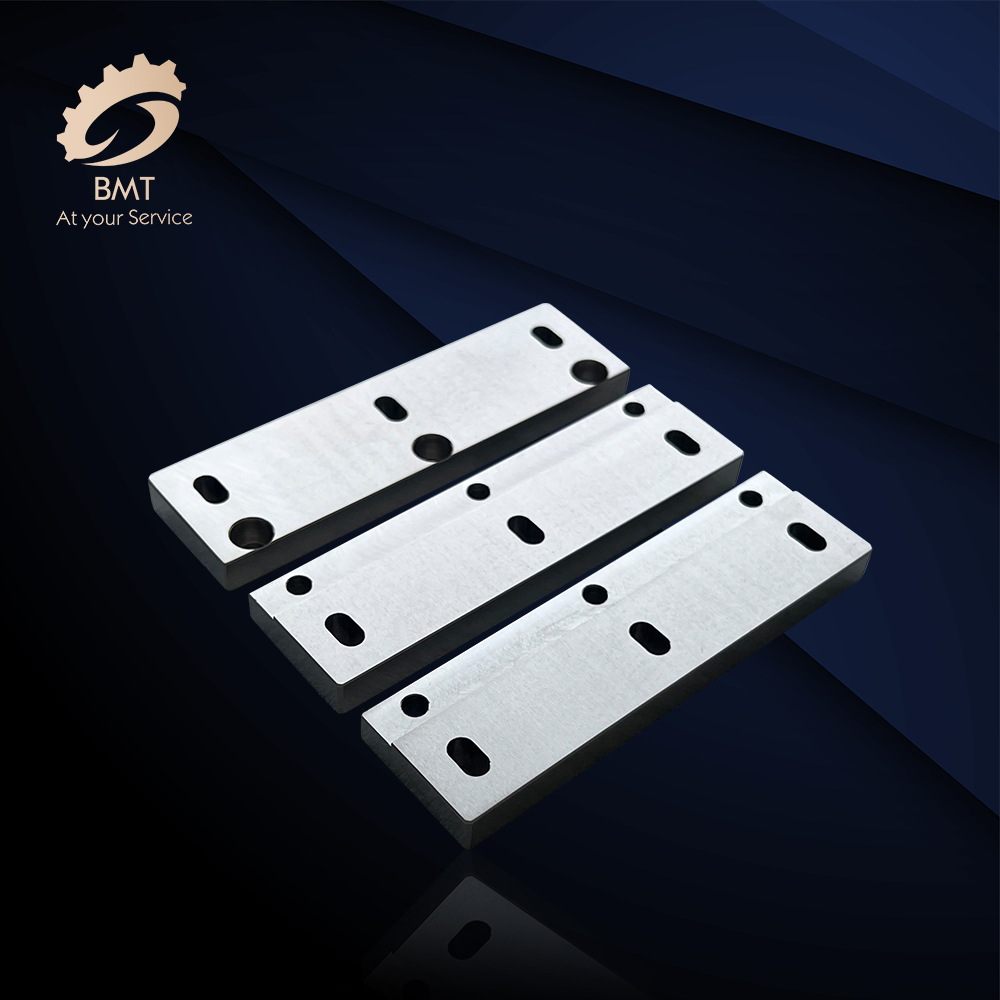

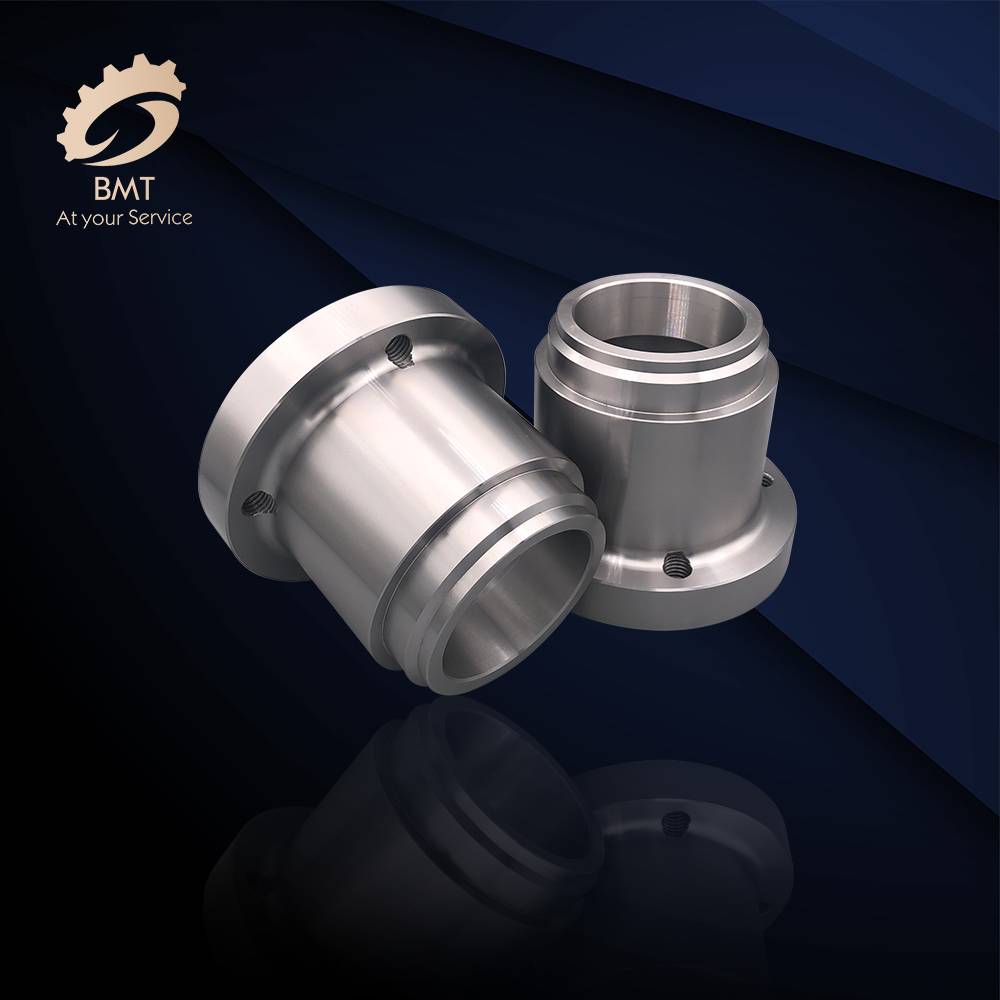

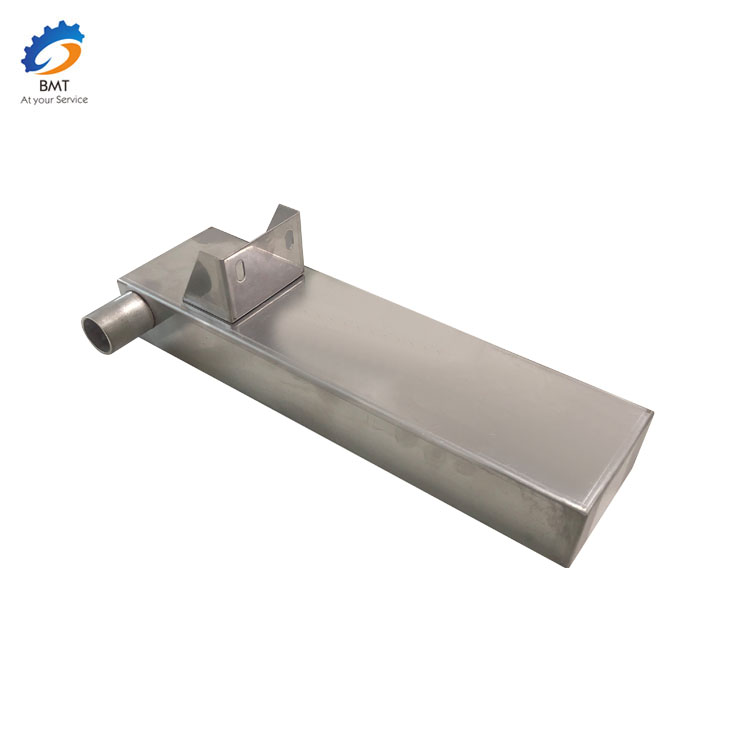

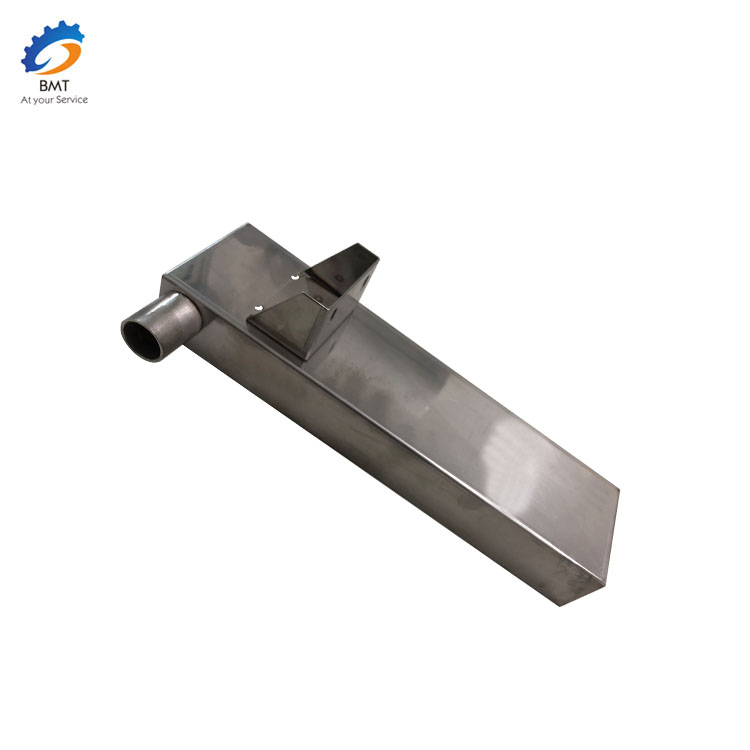

Sharaxaada Alaabta

Alaabaha Qaar Aan Sameyno